Cutting-edge technology

SCALE unlocks the full potential of microalgae and its amazing biodiversity.

Vincent Usache, CEO of Microphyt

‘We are really proud to coordinate the SCALE project, which fosters the transition towards sustainably produced, microalgae-based ingredients for nutrition and wellness. SCALE is a key milestone for the company and for each partner as it unlocks the full potential of microalgae and its amazing biodiversity,’ said Vincent Usache, CEO of lead partner, Microphyt, a French SME developing nutrition and wellness solutions from microalgae.

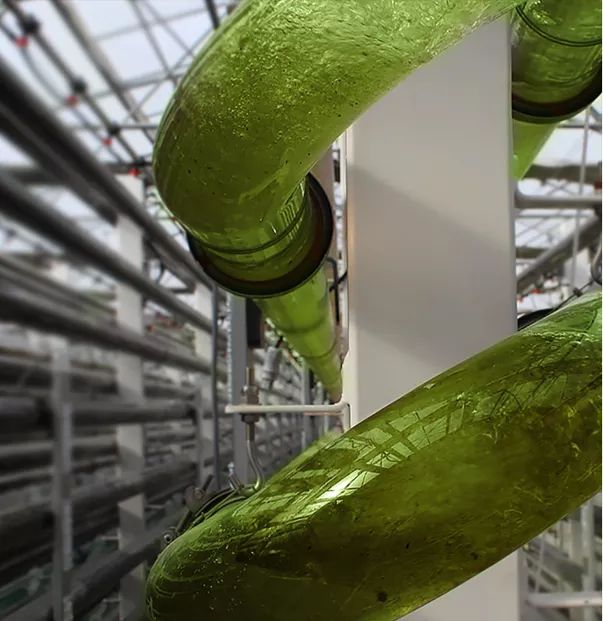

To tap into the diversity of microalgae, SCALE used Microphyt’s cutting-edge CAMARGUE photobioreactor technology. CAMARGUE reproduces the conditions of the marine environment, uses photosynthesis to cultivate a variety of microalgae species and makes it possible to identify active molecules and extract them from the microalgae.

SCALE upscaled the technology from a demonstration plant to an industrial-scale biorefinery with a continuous supply of large volumes of raw materials. Annually, the biorefinery can produce more than 100 tonnes of ingredients through an energy-efficient, zero-waste process that reduces greenhouse gas emissions by at least 20% compared with other state-of-the-art technologies.

Sustainable and healthy products

The SCALE ingredients are safe and can compete with their fossil-based counterparts on price and performance while having a much smaller environmental impact. As a source of vitamins, minerals and protein, microalgae can replace synthetic compounds and animal extracts such as Omega-3 from fish in food and food supplements. In feed, they address protein shortages, which are a major concern, particularly in aquaculture. For livestock, they offer a healthy alternative to animal meal, which can contain antibiotics and chemicals.

An industrial-scale plant is being constructed on our site and to produce safe, effective and sustainable ingredients. We currently have seven ingredients on the market.

Vincent Usache, CEO of Microphyt

Microalgae-based food supplements can also improve cognition, hearing and digestion. They also play a role in sports nutrition, weight management and pain prevention. Three such supplements – Brainphyt, GamePhyt and PhaeOptim – have been developed at the SCALE biorefinery. In particular, trials of Brainphyt on elderly people and GamePhyt on e-gamers have demonstrated their capacity to boost cognitive performance. PhaeOptim supports a healthy lifestyle and weight management and has been proven to significantly increase exercise capacity, improve cardiovascular health and maintain bone health.

Bio-based cosmetics

SCALE’s microalgae-based compounds can replace fossil-based ingredients, including petroleum derivatives, in cosmetic products such as anti-pollution, anti-acne and hydrating creams and haircare treatments. Several skincare products have been formulated. Among them: Luteana relieves sensitive skin; Renouvellance activates the skin’s defences against external stresses for a healthier appearance; PhycoSi improves the skin’s elasticity and firmness and protects and restores its surface; PhycoAge combats the signs of ageing.

'It's a great pleasure to collaborate with our partners, to see an industrial-scale plant being constructed on our site and to produce safe, effective and sustainable ingredients. We currently have seven ingredients on the market, and with our upcycled cosmetic ingredient PhycoSi, the SCALE project's biorefinery concept is now a reality,' added Vincent Usache.

Microalgae driving the creation of jobs

The biorefinery has boosted the economy in the coastal and rural area where it is located. It has created 40 direct jobs in production, engineering, maintenance, R&D, marketing and administration, including by training and employing young graduates, such as methods engineer Julie Ponchart.

Microphyt ideas and the sense of its commitment to a more virtuous world thanks to the power of microalgae really interested me.

Julie Ponchart, SCALE methods engineer

‘I'd heard about Microphyt and its innovative biorefinery project. Its ideas and the sense of its commitment to a more virtuous world thanks to the power of microalgae really interested me. That's rare in the industrial sector. I applied spontaneously, and Microphyt trusted me. Once you graduate from engineering school, those who go into industrial processes generally work in a laboratory or on modelling software but rarely in a production plant with a very operational position and responsibilities. I appreciate my chance, and I'm delighted to be part of this adventure,’ she said.

Furthermore, the establishment of local supply chains has given rise to a need for logistics, transport and other services, creating around 200 indirect jobs.

Replication of the plant in rural areas close to water bodies is planned and should provide similar levels of employment. It should also contribute to the wider uptake of microalgae-based ingredients, thereby helping to overcome the challenges currently facing food production systems.

Further collaboration

SCALE brought together 11 partners from four European countries: France, Norway, Spain and the United Kingdom. They came from different stages of the value chain: from raw material suppliers to producers of high-value products. Partners included Spanish food supplement producer and medicinal plant grower Plameca; French high fashion and cosmetics brand Chanel; and French animal nutrition group Lallemand.

The project has established five cross-sectoral interconnections between the microalgae sector and the food, food supplement, feed, cosmetics and technology industries. The skills and knowledge gained through these links will afford opportunities for further collaboration on bio-based ingredients.