It is standard procedure in the meat industry to turn an entire animal into food products. The fishing industry is a very different story. Every year, Europe’s fishing sector processes over 5 million tonnes of fish. However, nearly 70 % end up as sidestreams that are either used for low-value purposes or disposed of. This is costly for businesses.

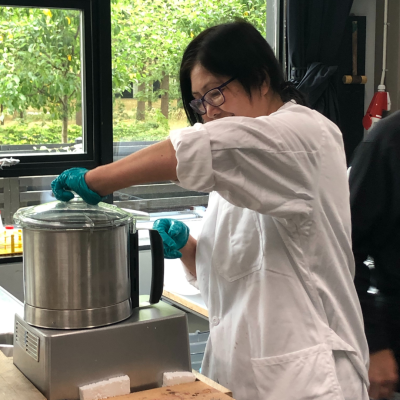

When the fillet itself is removed from a fish, sidestreams that can serve as high-value products usually become animal feed or get discarded. The way fish is processed needs to change to take advantage of valuable nutrients. The CBE JU-funded WASEABI project has introduced technological solutions to produce nutritional products and ingredients. The results were published in the journal ‘Food Chemistry’.

Researchers at the project partner Chalmers University of Technology in Sweden have developed sorting technology that obtains five good cuts from fish, including the head, tail and backbone, in addition to the fillet. This means that the fish is now separated into five clean parts instead of one. The five different cuts can be sold for the production of food raw materials and ingredients. A herring processing plant in Sweden is currently implementing the new method.

From head to tail, making the best use of fish

‘With our new sorting method, the whole fish is treated with the same care as the fillet. The focus is on preserving quality throughout the entire value chain. Instead of putting the various sidestreams into a single bin to become by-products, they are handled separately, just like in the meat industry,’ explains the study’s research lead Ingrid Undeland, Professor of Food Science at the Department of Biology and Biological Engineering at Chalmers in a news release posted on ‘EurekAlert!’. ‘Our study shows that this type of sorting technology is important, particularly as it means we can avoid highly perishable sidestream cuts being mixed in with the more stable cuts,’ comments first author Haizhou Wu, a researcher at Chalmers. ‘This new method brings fresh opportunities to produce high-quality food.’

Fish processing company Sweden Pelagic AB has already obtained good results after using the solution in its production process. CEO Martin Kuhlin adds: ‘The sorting technology gives us many more opportunities to develop healthy, new and tasty foods and to expand our product range. This year, we estimate we’ll produce around 200-300 tonnes of mince from one of the new cuts, and we aim to increase that figure year on year. The interest is there, in the food industry and public meal production segments like school catering.’

The 4-year WASEABI project aims to optimise the use of seafood sidestreams by developing new methods to produce nutritious and tasty ingredients. It ends in September 2023.

With our new sorting method, the whole fish is treated with the same care as the fillet

Ingrid Undeland, Professor of Food Science at the Department of Biology and Biological Engineering at Chalmers