FARMYNG

FlAgship demonstration of industrial scale production of nutrient Resources from Mealworms to develop a bioeconomY New Generation

FlAgship demonstration of industrial scale production of nutrient Resources from Mealworms to develop a bioeconomY New Generation

The world’s population is increasing rapidly and is set to reach 10 billion people by 2050 – almost one-third higher than it is currently. At the same time, the increasing demand for protein from animal and fish is putting tremendous strain on our ability to increase feedstock demand. Currently, the preferred source of protein for animal food is fish meal. However, meeting growing demand is unsustainable and likely to generate economic, social, environmental and health issues.

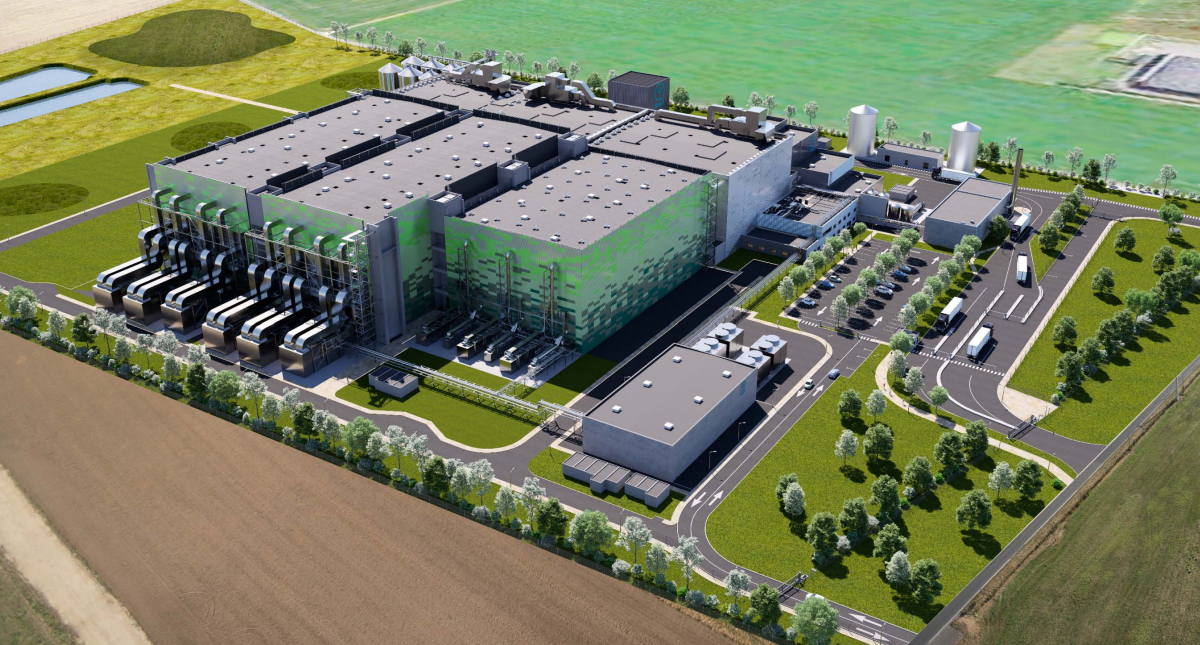

A potential alternative solution lies in replacing fish meal with insect sources, specifically mealworm. Insects multiply rapidly and are highly effective in converting organic matter from vegetal by-products. The FARMYNG project seeks to develop insect breeding and transformation to produce animal nutrition on an industrial and automated scale. It will demonstrate the first-of-its-kind bio-based value chain capable of producing sustainable, safe and premium feed products from mealworms, and doing so on a large-scale.

The FARMYNG approach can convert mealworms into sustainable proteins and lipids for fish feed and pet food end markets. This approach is environmentally friendly, producing no waste. Insects also emit less greenhouse gases and ammonia and use less water and land than other animal protein value chains. The FARMYNG project will set a new level of production for insect protein production.

The overall objective of the FARMYNG project is to create the world’s first industrial process for producing safe proteins from breeding insects and transforming them into animal nutrition sources. In addition, it will deliver the following:

The FARMYING project seeks to deliver the following impacts. It will: