EFFECTIVE

Advanced Eco-designed Fibres and Films for large consumer products from biobased polyamides and polyesters in a circular EConomy perspecTIVE

Advanced Eco-designed Fibres and Films for large consumer products from biobased polyamides and polyesters in a circular EConomy perspecTIVE

Polyamides (nylon) and polyesters are two of the most widespread families of polymers, with applications spanning from garments, carpets and sportswear to automotive parts, packaging materials, fishing products, and electric and electronic components. In recent years, many producers have been striving to increase the sustainability of such products at affordable prices, which implies not only the use of bio-based materials but also a sustainable end-of-life of the products.

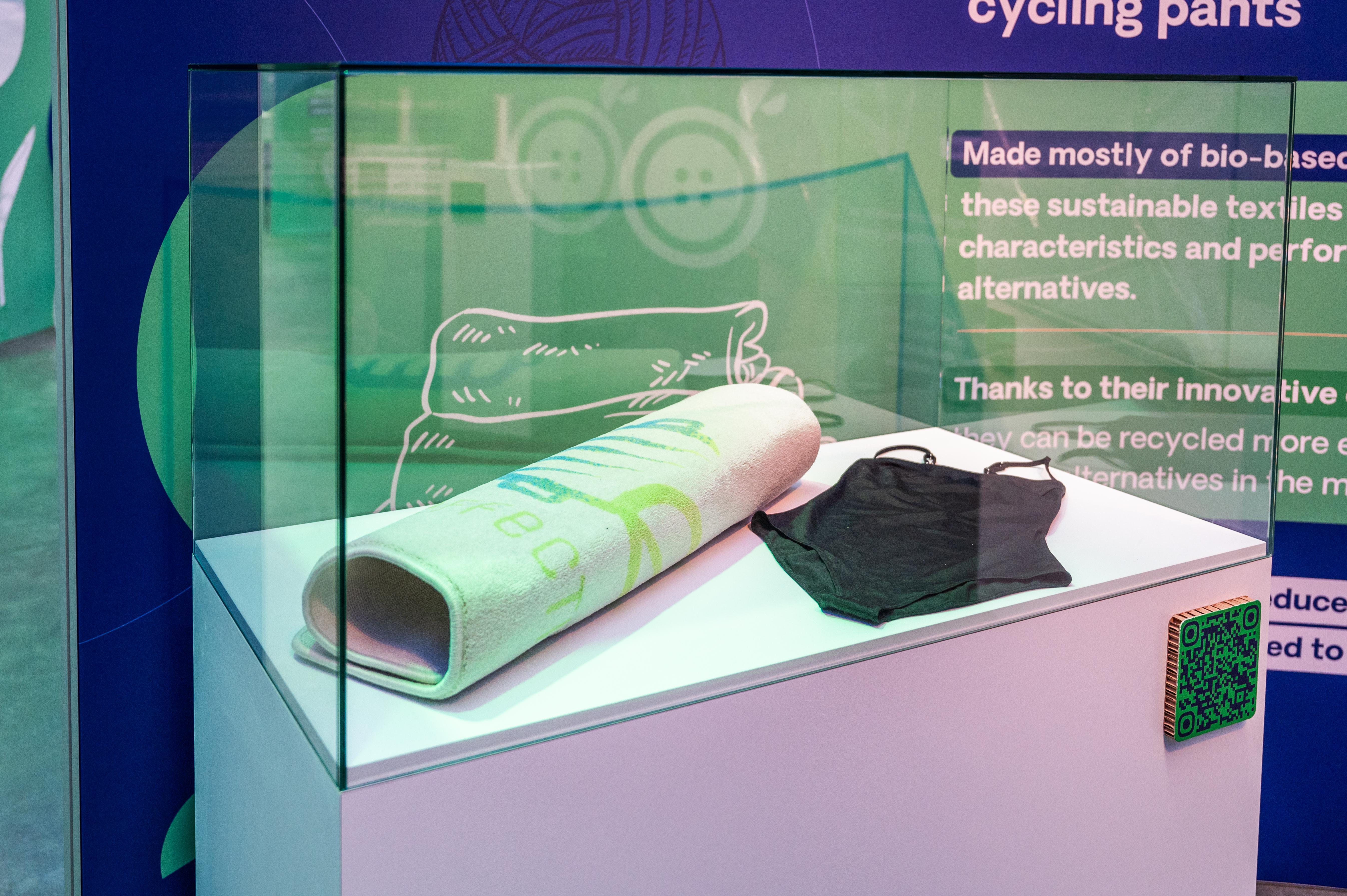

The EFFECTIVE project demonstrated first-of-their-kind and economically viable routes to produce bio-based polyamides and polyesters from sustainable renewable feedstock. The project produced bio-based fibres and films with enhanced properties, market competitiveness and increased sustainability.

EFFECTIVE used these materials to produce consumer products for different markets, such as textiles, construction, automotive, and packaging. The project’s team also proved their replication potential in fishing, engineering plastics, agriculture, hygiene, and personal care sectors.

The overarching objective of the EFFECTIVE project was to demonstrate innovative and economically viable routes to produce bio-based polyamides and polyesters from renewable feedstocks.

Key scientific and technological, scale-up and product objectives included:

Specific environmental objectives included: